What are the shortcomings of 3D printing tungsten alloy

Release time:

Dec 27,2024

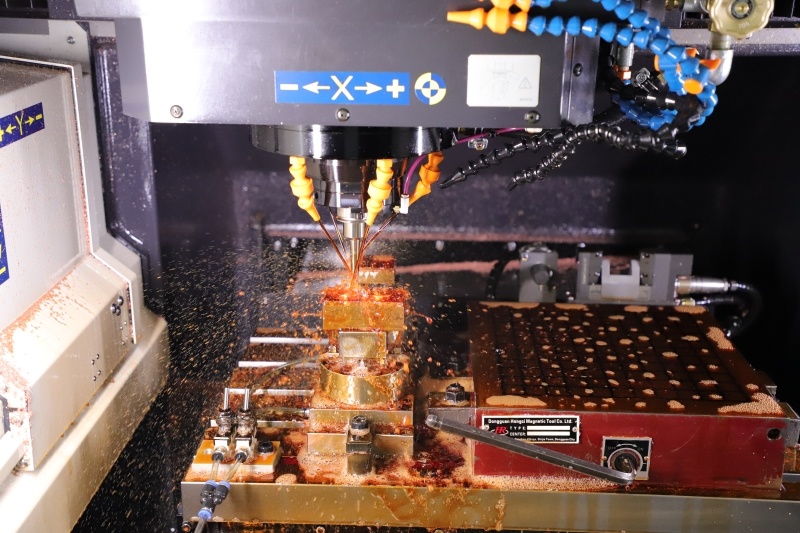

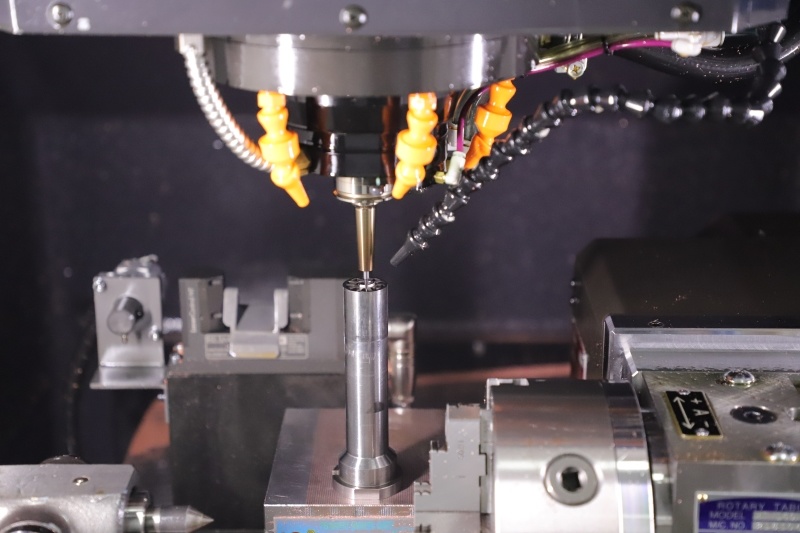

Tungsten alloy powder is an alloy with tungsten as the hard phase and cobalt, nickel, iron, and copper as the bonding phases. Due to its high melting point, hardness, and brittleness, it is difficult to process and even impossible to prepare tungsten parts with complex shapes. However, as long as there is a reasonable process, tungsten can be produced into materials through powder metallurgy, extrusion, forging, rolling, spinning, and drawing. It is worth mentioning that in recent years, the emergence of 3D printing technology has provided an effective method for manufacturing tungsten parts with complex shapes.

Tungsten alloy powder is an alloy with tungsten as the hard phase and cobalt, nickel, iron, and copper as the bonding phases. Due to its high melting point, hardness, and brittleness, it is difficult to process and even impossible to prepare tungsten parts with complex shapes. However, as long as there is a reasonable process, tungsten can be produced into materials through powder metallurgy, extrusion, forging, rolling, spinning, and drawing. It is worth mentioning that in recent years, the emergence of 3D printing technology has provided an effective method for manufacturing tungsten parts with complex shapes.

In 3D printing, selective laser sintering (SLS) or electron beam selective melting (EBM) can directly print and sinter metal powder into parts, and have been successfully applied to titanium and stainless steel. However, for tungsten alloys, there are still shortcomings in using SLS or EBM treatment, as the melting points of tungsten (3410 ° C) and metal elements such as cobalt (1495 ° C), nickel (1453 ° C), iron (1538 ° C), and copper (1083 ° C) differ significantly.

Specifically, when the temperature reached by the laser can melt tungsten metal, the binder such as cobalt element will evaporate and solidify, making the alloy structure unable to meet the requirements as a tungsten alloy. If the sintering temperature is controlled within the range where light melts cobalt, it will cause the collapse of the formed structure and uneven density distribution. Attention: The role of binders in alloys is to enhance their properties and improve the wear resistance of the product.

However, compared to traditional manufacturing techniques, 3D printing technology is simpler to operate and can produce products with complex shapes without the need to manufacture molds in advance. Therefore, it is suitable for rapid single piece and small batch part manufacturing, manufacturing of complex shaped parts, and manufacturing of difficult to handle materials. In addition, this technology also has the advantages of achieving structural optimization, saving materials, and conserving energy.