SOLUTIONS

Automotive

Electronic

Home appliance

Plastic products

Other fields

ABOUT US

We are a precision non-standard parts processing factory with 108 employees.

We are committed to precision machining of tungsten carbide, silver tungsten(AGW), pure tungsten.

As the years have passed over several decades, we have delved deep into the low-key yet profoundly significant field of tungsten processing, marching forward with unwavering determination and an indomitable spirit. Every colleague here has poured their most glorious youth and lifelong efforts into this industry. We have taken root in this field, using the passage of time to write the story of our perseverance and interpreting our craftsmanship with passion. In this seemingly narrow specialized domain, we have carved out a brilliant world of our own.

Based on our deep processing experience, we are committed to providing customers with the highest quality products to meet their diverse needs with exquisite craftsmanship and strict quality control, whether in the medical, military, automotive, industrial or beauty fields.

OUR ADVANTAGES

Professional & efficient

We have a professional design team that combines industry characteristics and customer needs to quickly propose reasonable design solutions.

Customized services

Provide personalized customized services to customers, tailor mold design solutions based on their specific needs and product characteristics, ensuring that the molds can meet their special requirements.

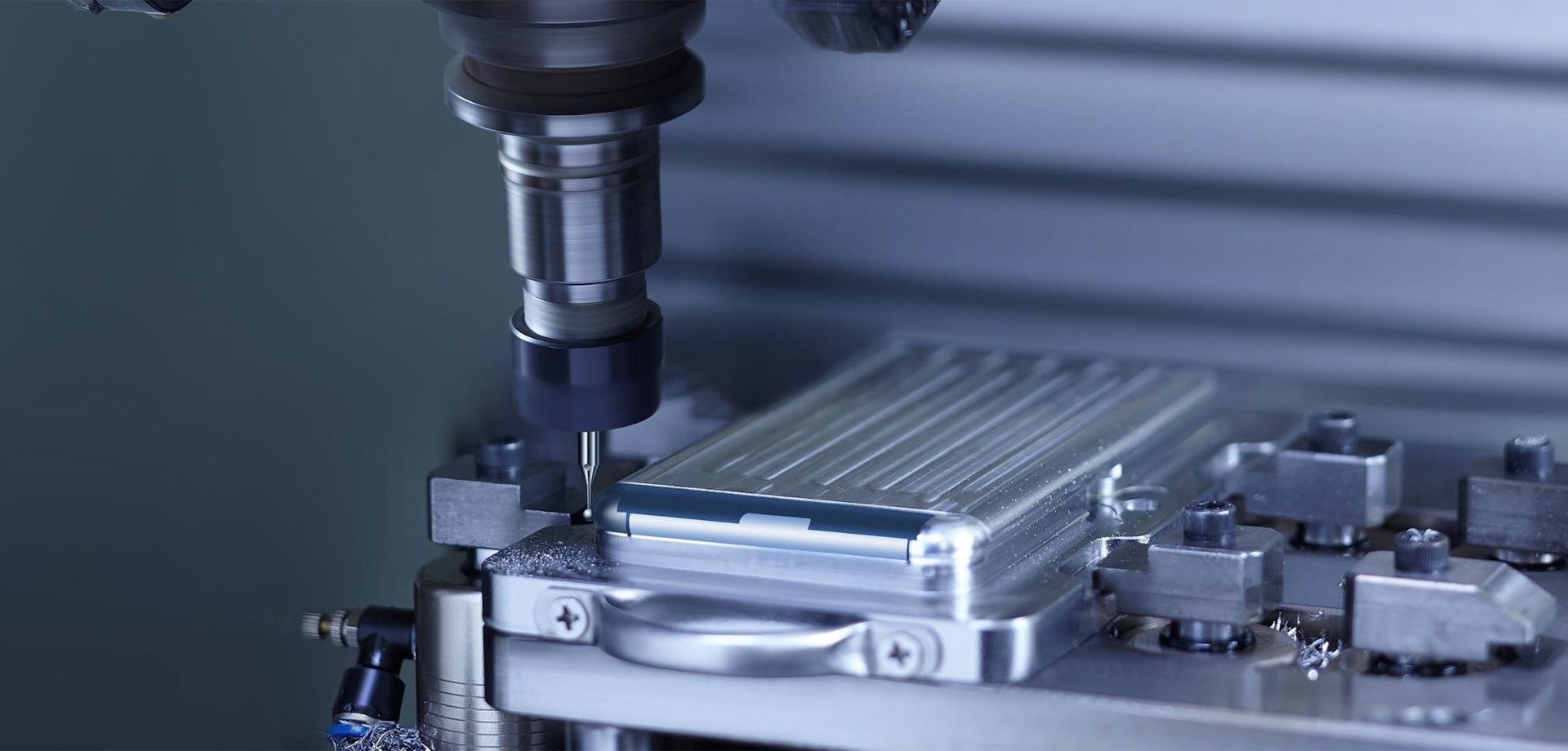

Advanced technology and equipment

Advanced production equipment can also ensure the manufacturing accuracy and surface quality of molds, providing customers with higher quality products.

Comprehensive service support

From project acceptance to project acceptance, the company will strictly control every step to ensure customer satisfaction.

NEWS

What are the shortcomings of 3D printing tungsten alloy

Tungsten alloy powder is an alloy with tungsten as the hard phase and cobalt, nickel, iron, and copper as the bonding phases. Due to its high melting point, hardness, and brittleness, it is difficult to process and even impossible to prepare tungsten parts with complex shapes. However, as long as there is a reasonable process, tungsten can be produced into materials through powder metallurgy, extrusion, forging, rolling, spinning, and drawing. It is worth mentioning that in recent years, the emergence of 3D printing technology has provided an effective method for manufacturing tungsten parts with complex shapes.

Dec 27,2024

3D printing can optimize the through electrode of electrochemical reactors

Renewable energy is in high demand, like the stars of tomorrow. How to optimize the efficiency of renewable energy, 3D printing is playing an important role as a feasible and universal "fast track method" for circulating electrodes, and a way to maximize reactor performance! Scientists and engineers at Lawrence Livermore National Laboratory LLNL use 3D printed electrodes (FTEs) to convert CO2 and other molecules into the core components of good electrochemical reactors.

Dec 27,2024

Shouhua Finance Network plans to rebuff HK$39.8 million to buy commercial properties in Central

Shouhua Finance Network plans to use HK$39.8 million to purchase the 17th floor of China Consortium Building, 64 Connaught Road Central, and 133 Des Voeux Road Central, as well as toilets A and B for office properties.

Dec 27,2024

PARTNERS

Give us an email to surprise you

Note: Please leave your E-mail address and our professionals will contact you as soon as possible!